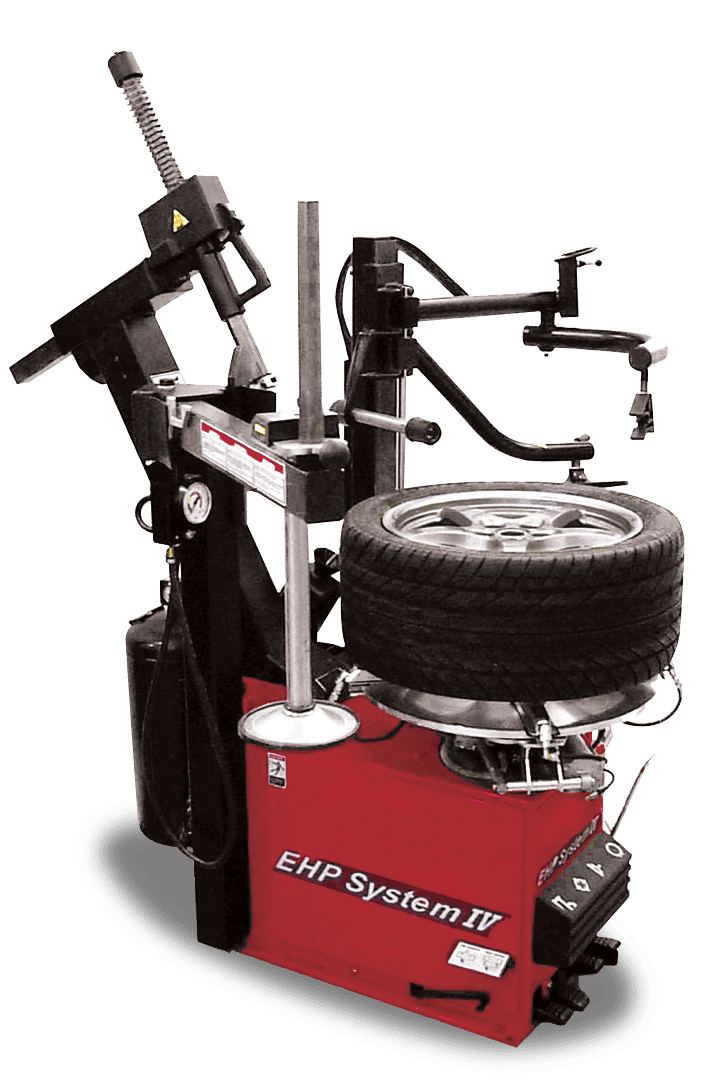

John Bean System IV-E

Tilt Tower Tire Changer

Part Number: EEWH553AE

The System IV-E Two-Speed tire changer can handle a wide range of passenger car and light truck wheel and tire assemblies from OEM’s or aftermarket. The two-speed advantage of 14 RPM allows the technician faster throughput through the bay. The System IV-E features pneumatic locking of the mount/demount head offset, which provides maximum cosmetic safety for expensive wheels and significantly reduces the risk of wheel or tire damage. (Shown with Optional Pneumatic Bead Assist and Safety Restraint Arm).

-

Ergonomically Positioned Bead Breaker Control – Pedal is positioned away from the bead breaker with a guard, preventing the operator from accidentally stepping on an activating it while standing next to the bead breaker.

-

Integrated Pressure Limiter – Stops air flow once pressure has reached 55 PSI (3.5 Bar), thereby preventing accidental tire over-inflation.

-

Adjustable Four-Jaw Clamp – Self-centering nylon-covered clamps grip securely and protect the wheel. Reduced-angle jaws ensure no slippage. Air inflation jets assist bead seating.

-

Extra Wheel Protection – Replaceable nylon inserts for demount heads prevent wheel scratching. Replaceable polymer remount heads are also available for extended protection.

-

Twin-Cylinder Clamping – Two power clamping cylinders provide uniform clamping pressure and increased clamping power.

-

Bead Breaker – Provides precise power and can be toggled with the foot pedal as needed. Both the stiffest and the softest sidewalls are a snap. No damage to tires while loosening the bead.

-

Pneumatic Bead Assist – The standard pneumatic bead assist features a three-piece design with a top roller, pressing foot and lifting disc. Each piece provides a specialized function that assists a single operator in mounting/demounting low-profile and high-performance tires.

-

Adjustable two position bead breaker with robust, anti-skid contact pad and over-sized bead-breaking blade.

-

Pneumatically controlled movement of the mounting head toward the wheel.

-

Mounting column can be tilted back to increase the space the technician has to maneuver the wheel and tire assembly.

-

Polymer inserts protect the wheel and prevent clear-coat damage.

-

Pedal operated inflation.

- Ergonomically Positioned Bead Breaker Control – Pedal is positioned away from the bead breaker with a guard, preventing the operator from accidentally stepping on an activating it while standing next to the bead breaker.

- Integrated Pressure Limiter – Stops air flow once pressure has reached 55 PSI (3.5 Bar), thereby preventing accidental tire over-inflation.

- Adjustable Four-Jaw Clamp – Self-centering nylon-covered clamps grip securely and protect the wheel. Reduced-angle jaws ensure no slippage. Air inflation jets assist bead seating.

- Extra Wheel Protection – Replaceable nylon inserts for demount heads prevent wheel scratching. Replaceable polymer remount heads are also available for extended protection.

- Twin-Cylinder Clamping – Two power clamping cylinders provide uniform clamping pressure and increased clamping power.

- Bead Breaker – Provides precise power and can be toggled with the foot pedal as needed. Both the stiffest and the softest sidewalls are a snap. No damage to tires while loosening the bead.

- Pneumatic Bead Assist – The standard pneumatic bead assist features a three-piece design with a top roller, pressing foot and lifting disc. Each piece provides a specialized function that assists a single operator in mounting/demounting low-profile and high-performance tires.