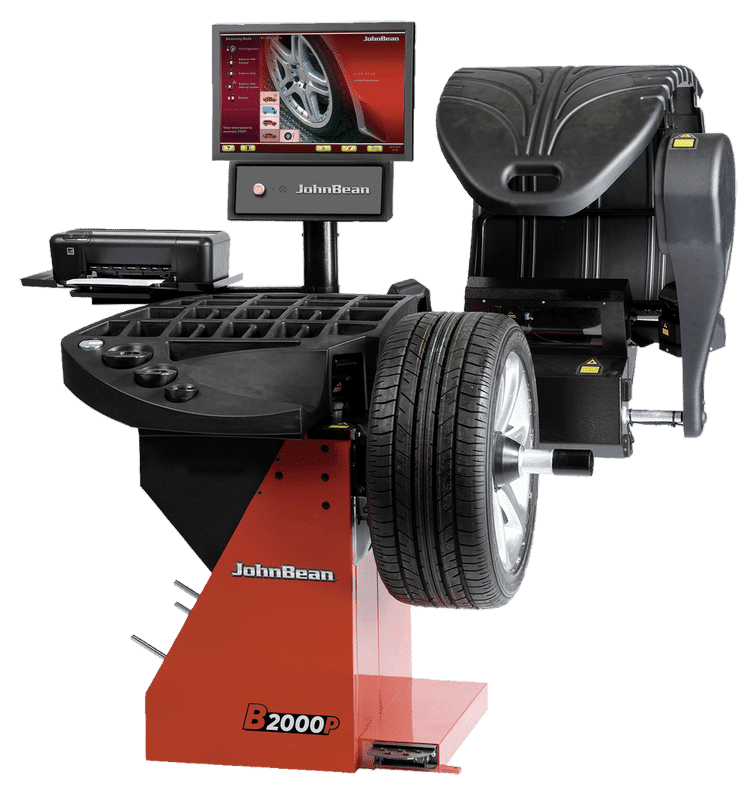

John Bean B2000P Wheel Balancer

Diagnostic Wheel Balancer Premium Service

Part Number: EEWB582AP230

The B2000P is the only automated diagnostic wheel balancing system that offers touchless measurement and analysis. Automatic inputs remove the chance for error and inaccurate results. When combined with precise wheel balancing, the Runout Force Vectoring (RFV) diagnostics assure uniformity based total ride quality.

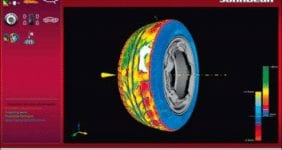

- Runout Measurement – Hundreds of thousands of measurement points are taken with a resolution of 0.004″ (0.1 mm) to create a 3D model of the tire and wheel assembly.

- Laser Based Runout – Quickly and easily provides advanced geometry related measurements, using technology that surpasses the performance of mechanical roller-based systems.

- Automatic 3D Tire Laser Mapping System – High-resolution camera and laser based topography mapping emulated the same technology used by tire manufacturers in industrial applications. Tire tread and sidewall color analysis allows depth, wear and abnormalities to be displayed in a simple to interpret format.

- Automatic Inputs – Optical scanners automatically measure the wheel. The scanners recognize the wheel type/edge. Correct weight type and size are shown to aid productivity.

- Automatic Balance Measurements – The color display shows the location of any imbalance and identifies the optimal tape of clip-on weight location. Automatically measures assembly and rim runout and calculates runout force vectoring for a quick fix match-mounting solution.

- Automatic Behind the Spoke Weight Placement – A laser indicates the exact weight location behind the spoke

- Patented, Automatic Power Clamp – The electro-mechanical power clamp device always clamps the wheel accurately with a constant force, providing a reliable and consistent condition to assure accurate and repeatable measurements.

- Included Accessories:

- Four Cone Kit (EAK0309J28A)

- Weight Pliers (00058839000)

- Accessory Kit for Power Clamp (EAA0307G54A)

- Color Ink-Jet Printer (EAK0221992A)

DOWNLOAD BROCHURE

KEY FEATURES

3D IMAGING DIAGNOSTICS

The type, size and position of a defect in the tire are identified, measured and visualised by non-contact 3D imaging technology.

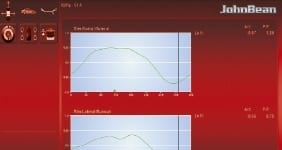

RADIAL RUN-OUT

Peak-to-peak and 1st harmonic graphs of wheel run-out are provided for an easy diagnostic of the issues. Rim run-out and matching information are provided when necessary.

ENHANCED USER INTERFACE

Highly intuitive and fast touch-screen monitor with large digits, coloured weight position indicators and enhanced user interface – improved intuitiveness and ergonomics.

MATCH-MOUNTING

Radial run-out diagnosis of the wheel is performed during unbalance measurement, hence without compromising on productivity. High run-out is automatically detected during rim diagnosis, providing match-mounting.

EASYWEIGHT™

Pinpoint laser identifies exact weight placement location for increased accuracy and efficiency.

OVERSIZE SHAFT

The 225 mm length allows the use of stud-hole flanges and other accessories for almost every type of rim.

RIM SCANNER

The rim scanner automatically detects rim diameter and offset as well as the number and position of rim spokes. Then it automatically chooses balancing mode, weight types and weight positions.

SPLIT WEIGHT MODE

Hides adhesive weights behind two adjacent spokes so they cannot be seen from the outside.

POWER CLAMP™

Patented automatic Power Clamp™ electromechanical clamps the wheel accurately with a constant force, reducing the opportunity for chasing weight.

QUICKBAL™

30% reduced cycle time, less than 4.5 seconds, maintaining the same high accuracy.

VPI TECHNIQUE

Measurement system for high precision and repeatability.